Our Steel Chains are made to UK and international standards with the links side welded for extra strength. They are suitable for all general purpose, engineering, industrial, agricultural and marine applications and are available in a variety of protective finishes such as zinc plated, hot galvanised and black.

Most importantly, they are commercial chains. Whilst, therefore, each has been quality tested, none is certified for heavy loadbearing purposes and should not be used for overhead lifting, load binding or towing. To make selection easier in this respect, we have provided a general guide for each chain. Please refer to the "Maximum Load" information under the Specification tab for each.

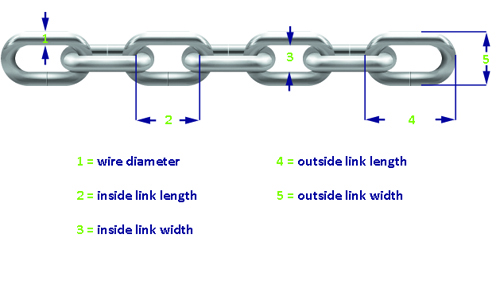

Understanding chain measurements

Chain Finishes

We supply chains in a variety of finishes:-

Hot Galvanised

A thin layer of zinc is applied to each link of chain after manufacture by passing it through a bath of molten zinc. The resultant coating is dull grey in colour with an uneven but fairly durable surface. This protects the steel from the elements and therefore corrosion. Galvanised chain is widely used where rust resistance is required and is therefore ideal for outside applications.

Zinc Plated

A similar process to galvanisation in that a zinc finish is used to protect the metal against rust. A far thinner layer is applied, however, than for hot dip galvanise making it less strong and less resistant to corrosion. Zinc plated items are therefore not suited for use outdoors. Identified by its smooth bright, bright appearance.

Black Plated

Black plating - also known as black japanning - is a process where black lacquer or varnish with a high bitumen content is applied directly to the chain and baked at 200º C. The resulting finish dries quickly, is smooth, shiny and durable. Popular for decorative reasons, it also protects chain against rust. Black chain is therefore often used in fencing and gardening.

Hardened

Many types of steel are heat treated to increase toughness and resistance to wear. Known as hardening, this process involves heating steel then cooling it rapidly. Hardening falls into two categories - Through-hardening and Case-hardening.

Through-hardening is used on medium and high carbon steels and treats the entire item, increasing its strength throughout.

Case-hardening is used on steel with a low carbon content. Carbon is added to the surface of the item and some of the interior. The result is a combination of high surface hardness and internal toughness.

Hardened Boron Alloy

Boron steel is one of the strongest types of metal available. It is extremely durable and can only be cut using specialist laser technology or cutting techniques. The choice for high level security.

Chain is a specialist commodity and advice is frequently required. If you are uncertain as to which chain you need then please contact us.